Time:2025-07-15 Views:1 source:News

Embossing time is a critical parameter when using embossing machines on silk fabric, as it directly influences the clarity of the pattern, fabric integrity, and overall quality of the finished product. Silk, a delicate and natural protein fiber, requires precise timing to achieve a crisp, durable emboss without causing damage such as scorching, tearing, or loss of softness.

The ideal embossing time for silk typically ranges from 2 to 8 seconds, depending on factors like fabric thickness, desired pattern depth, and the temperature of the embossing die. Thinner silk fabrics (e.g., chiffon or organza) require shorter times (2–4 seconds) to prevent over-processing, which can weaken the fibers or create a stiff, unnatural texture. Heavier silk varieties (e.g., satin or dupioni) may need 5–8 seconds to ensure the pattern penetrates the denser weave, resulting in a visible and long-lasting impression.

Temperature and pressure work in tandem with time to affect results. Most silk embossing is performed at temperatures between 80°C and 120°C. Higher temperatures can reduce the required time, but they also increase the risk of fiber damage. For example, a 100°C die with moderate pressure (2–3 bar) might achieve a sharp pattern on silk satin in 5 seconds, whereas lowering the temperature to 80°C would necessitate extending the time to 7 seconds to achieve the same effect.

Operators must also consider the pattern’s complexity. Intricate designs with fine details require longer contact time to ensure all elements are fully transferred, but this must be balanced with the fabric’s tolerance. Pausing too long can cause the silk to shrink or discolor, especially in areas with high thread count.

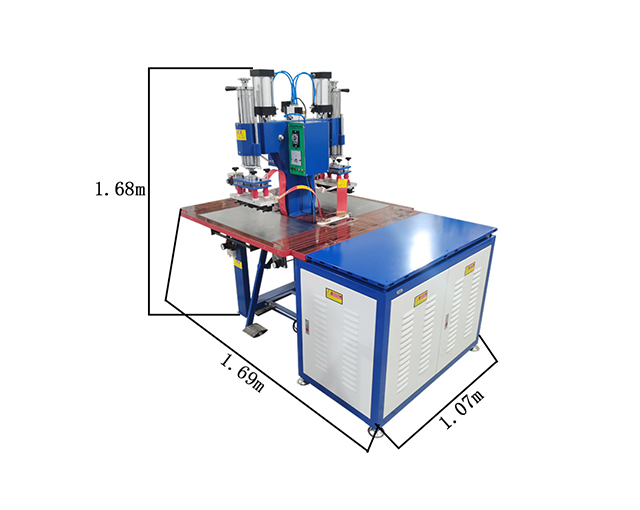

Another factor is the embossing machine type. Manual machines often require longer, more controlled timing, while automated models with precision timers can maintain consistent intervals, reducing human error. Post-embossing care, such as cooling the fabric under pressure for 1–2 seconds before release, helps set the pattern and prevent it from fading during washing or handling.

mastering embossing time for silk involves balancing fabric type, temperature, pressure, and pattern complexity to achieve a flawless, durable finish that enhances the fabric’s natural elegance without compromising its integrity.

Read recommendations:

Vertical Skin Vacuum Packaging Machine

Automatic HF round table welding and cutting machine

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.