Time:2025-04-18 Views:1 source:News

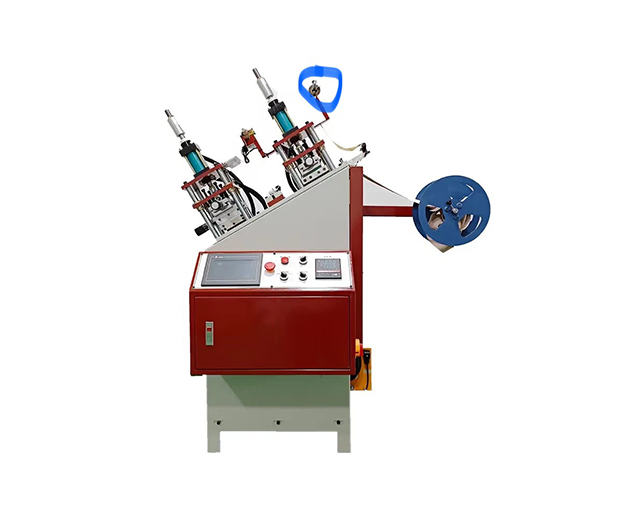

The frequency - conversion plate embossing machine is a sophisticated piece of equipment used in various industries for creating embossed patterns on plates. Mastering its operation skills is crucial to ensure high - quality embossing results and efficient production.

Initial Setup and Preparation

Before starting the machine, proper initial setup is essential. First, check the power supply to ensure it meets the machine's requirements. The frequency - conversion plate embossing machine usually operates on a specific voltage and frequency range. Any deviation can lead to improper functioning or even damage to the machine. Next, inspect the embossing dies. Make sure they are clean, free from any debris or damage. The dies play a vital role in creating the embossed pattern, and any imperfections on them will be transferred to the plates. Install the dies correctly in the machine, ensuring a secure fit. Also, adjust the pressure settings according to the thickness and material of the plates to be embossed. For thinner materials, lower pressure may be sufficient, while thicker and more rigid materials require higher pressure.

Machine Operation During Production

When starting the machine, begin with a slow speed. This allows for a smooth start and gives the operator a chance to monitor the machine's performance. As the machine runs, observe the embossing process closely. Check if the embossed pattern is being formed evenly across the plate. If there are any uneven areas, it could be due to uneven pressure distribution. In such cases, stop the machine and re - adjust the pressure settings. The frequency - conversion feature of the machine allows for precise control of the motor speed. Adjust the speed based on the complexity of the embossed pattern. For intricate patterns, a slower speed may be required to ensure accurate replication, while for simpler patterns, a higher speed can be used to increase production efficiency. Additionally, maintain a consistent feed rate of the plates into the machine. A fluctuating feed rate can result in inconsistent embossing quality.

Troubleshooting and Maintenance During Operation

During operation, be vigilant for any signs of trouble. If the machine makes unusual noises, it could indicate a mechanical problem, such as a loose component or a worn - out bearing. Stop the machine immediately and inspect for any visible issues. Another common problem is plate jamming. If a plate gets stuck in the machine, do not force it. Instead, carefully reverse the machine's operation or follow the manufacturer's instructions for safe plate removal. Regular maintenance is also an important part of operation. Lubricate the moving parts of the machine at regular intervals to reduce friction and ensure smooth operation. Check the electrical connections periodically to prevent any electrical malfunctions. By following these operation skills, operators can maximize the performance of the frequency - conversion plate embossing machine and produce high - quality embossed plates.

Read recommendations:

Slide Table rf High Frequency Welding Cutting and Embossing Machine Sport Shoe upper

Semi-automatic PVC/EVA bag making machine

Automatic rotary table high frequency welding machine with card loading and take out robot

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.