PET (Polyethylene Terephthalate) is a widely used thermoplastic polyester known for its excellent mechanical properties, clarity, and chemical resistance. When it comes to using embossing machines for PET plastic lampshades, several key factors need t

PU (Polyurethane) plastic, known for its excellent wear - resistance, flexibility, and durability, is widely used in the manufacturing of handrails. Embossing machines play a crucial role in enhancing the functionality and aesthetic appeal of PU plast

Embossing technology plays a dual role in camera leather cases: enhancing aesthetic appeal while significantly improving protective capabilities. By creating raised patterns or textures on the leather surface, embossing machines modify the material’s

The embossing machine for AGA (Amorphous Glycol - modified PET) industrial plastic has become an indispensable tool in the manufacturing of high - performance plastic products. AGA, a type of modified polyethylene terephthalate, offers enhanced proper

TPU (thermoplastic polyurethane) inflatable toys, such as pool floats, air mattresses, and children’s bounce houses, rely on embossing machines to achieve both functional integrity and aesthetic appeal. TPU is favored for its high elasticity, water re

When it comes to pet collars, comfort is of utmost importance, and the embossing machine plays a crucial role in achieving this while also adding aesthetic appeal. The process of creating comfortable embossing on pet collars involves careful considera

Embossing machines play a crucial role in adding aesthetic and functional features to TPU (Thermoplastic Polyurethane) mobile phone protective cases. TPU is a popular material for phone cases due to its excellent elasticity, durability, and scratch -

The design of high - frequency molds for garment embossing machines is a meticulous process that combines artistic creativity with engineering precision. These molds play a pivotal role in creating intricate patterns and textures on fabrics, enhancing

Thermoplastic Polyurethane (TPU) is a versatile elastomer that combines the properties of rubber and plastic, making it an ideal material for various applications, including dust covers. TPU dust covers are widely used in industries such as automotive

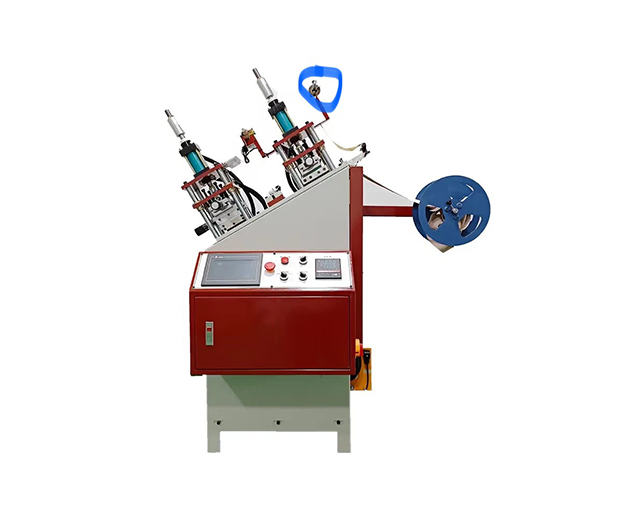

Complete control over products allows us to ensure our customers receive the best qualityprices and service. We take great pride in everything that we do in our factory.